Diapers: How Much Do You Know?

With the evolution of parenting concepts and the rise in disposable income, the baby diaper market has been expanding, transitioning from a discretionary product to a "must-have necessity." For modern parents, diapers are not only essential for ensuring a baby’s comfort and health but also for freeing up their hands, reducing parenting stress, and enhancing the overall experience of raising a child. Let’s dive into the structural design of diapers and their specific components.

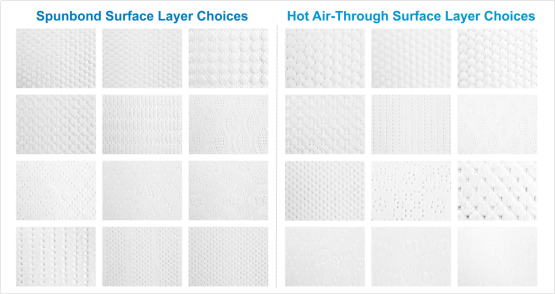

The top layer is in direct contact with the baby’s delicate skin, so it must be soft, breathable, and non-absorbent. Its primary role is to keep the baby’s bottom dry by quickly absorbing urine and preventing leaks. This layer is typically made of non-woven fabric, with hot-air non-woven fabric and spunbond non-woven fabric being the most common. Hot-air non-woven fabric offers better performance with a softer surface.

The ADL,located between the top layer and the absorbent core, serves to rapidly and evenly guide urine to the core for absorption, avoiding blockages and reverse flow caused by localized accumulation. Since a baby’s urine tends to be concentrated in one area, efficient dispersion is crucial to maintaining absorption performance. The fibers in this layer are mostly arranged longitudinally, allowing for temporary storage and rapid diffusion of liquid along the fibers until it is absorbed by the core. This design significantly enhances the diaper's absorption efficiency and dryness, ensuring wearing comfort.

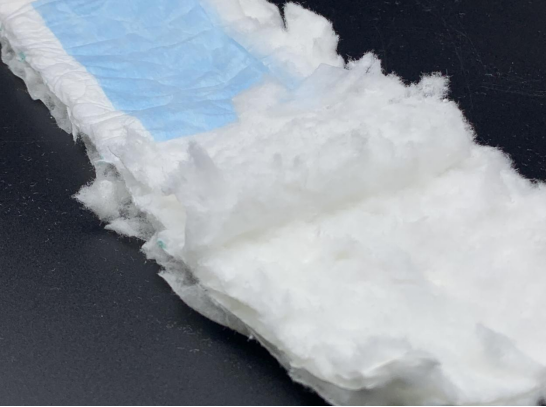

Diapers on the market generally feature two types of core structures:SAP Paper Core. This ultra-thin absorbent core is a mixture of dust-free paper, fluffy non-woven fabric, and superabsorbent polymer (SAP) in specific proportions. The dust-free paper channels urine to the SAP, where it is absorbed, while the fluffy non-woven fabric layer fixes the SAP in place.

Composite Core: Made from a combination of fluff pulp and SAP, this core uses wood pulp fibers to guide urine into the absorbent core, where the SAP locks in the liquid. However, due to the presence of wood pulp, issues like clumping and layer separation are more difficult to resolve.

The backsheet is the waterproof outer layer that prevents liquid from seeping through the diaper onto the baby’s clothing or surrounding environment. Diaper backsheets are available in PE films and breathable films. The former offers stronger waterproofing, while the latter ensures breathability for added comfort and dryness.