Technological Innovation in Diapers: Comprehensive Improvement from Performance to Comfort

The most prominent technological advancement in diapers lies in innovations in the "absorbent core-core structure," which directly determines absorption efficiency, comfort, and overall user experience. Therefore, for clients customizing diapers, the quality of the core is especially crucial, as it affects the diaper's water absorption capacity, speed, water retention, and whether any leakage or layering issues occur. This directly determines the performance and quality of the diaper, influencing the brand's development and market positioning.

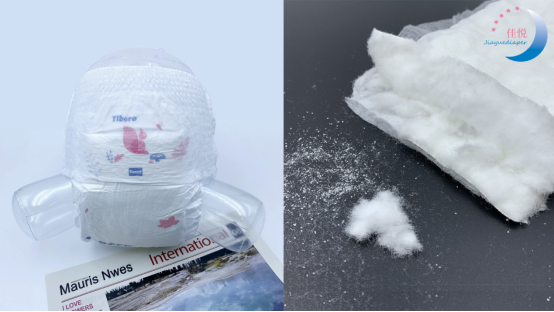

The first-generation diaper absorbent layer mainly consists of a pulp & SAP core, with a higher proportion of wood pulp, leading to relatively limited absorption capacity. These diapers are also bulkier and less breathable. This type of diaper is typically used in price-sensitive markets, particularly in developing and emerging markets in regions like Africa, the Middle East, Southeast Asia, and South America. Although their absorption performance is weaker, their low cost and simple structure still meet basic usage needs, making them the most common choice among consumers in these regions.

The second-generation diaper absorbent layer mainly uses an SAP paper & pulp core. Compared to wood pulp diapers, the speed of absorption has improved, but the absorbent layer is still relatively thick. Additionally, its flow ability and absorption strength have certain limitations, which can still lead to uneven absorption, layer breakdown, clumping, and consequently leakage and diaper rashes. Therefore, this type of high cost-effective diaper is more popular in regions such as Africa, Southeast Asia, and Russia.

The third-generation diaper absorbent layer uses an SAP paper core. The design of the absorbent layer gradually becomes thinner, primarily using imported SAP as the core material. Compared to the previous two generations, this type of diaper shows significant improvements in absorption capacity, fluid guidance, and water retention. Its excellent anti-reverse osmosis and fluid conduction properties make the diaper less likely to experience breakdowns, providing a more comfortable user experience. Currently, third-generation diapers are widely used in markets in China, Japan, South Korea, Russia, and Europe and the United States.